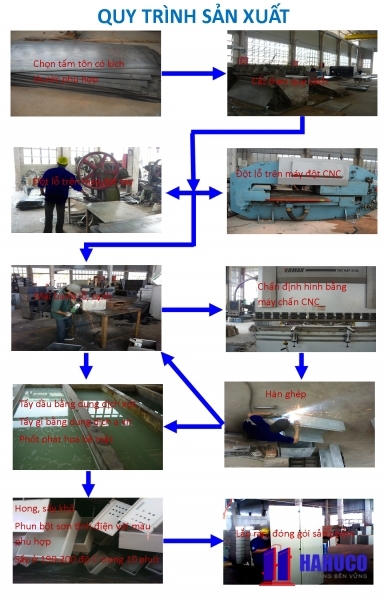

1. Select the plate with suitable size, cut to specifications => test

2. Hand Punching holes in the machine or the machine suddenly broke CNC => test

3. grinding, cleaning burrs => test

4. Got shaping => test

5. South graft and sanitary welds (if any) => check

6. Degreasing with a solution of caustic soda => test

7. pickling acid solution => test

8. Shaping the surface with chemicals dedicated => test

9. Phosphates surfaces => test

10. Wash water, dried => test

11. Spray Powder Coatings color matching => test

12. Drying temperature for 10 minutes 190-200oC

13. Check the product after painting

14. Assembling, packaging, finishing last test before storing

Note:![]()

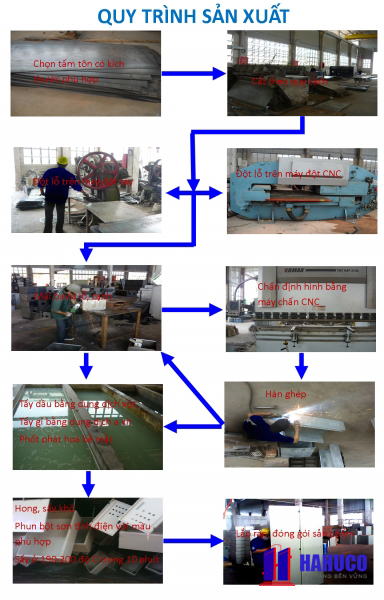

2. Hand Punching holes in the machine or the machine suddenly broke CNC => test

3. grinding, cleaning burrs => test

4. Got shaping => test

5. South graft and sanitary welds (if any) => check

6. Degreasing with a solution of caustic soda => test

7. pickling acid solution => test

8. Shaping the surface with chemicals dedicated => test

9. Phosphates surfaces => test

10. Wash water, dried => test

11. Spray Powder Coatings color matching => test

12. Drying temperature for 10 minutes 190-200oC

13. Check the product after painting

14. Assembling, packaging, finishing last test before storing

Note:

- For product is galvanized or stainless steel sheet: no use of the stages 7-12,

- For corrugated galvanized products through welding, the welding seams stage is treated with cold zinc paint

- For hot-dip galvanized products: do not use the 11 stages, 12 stages instead of zinc.

Việt Nam

Việt Nam  Tiếng anh

Tiếng anh