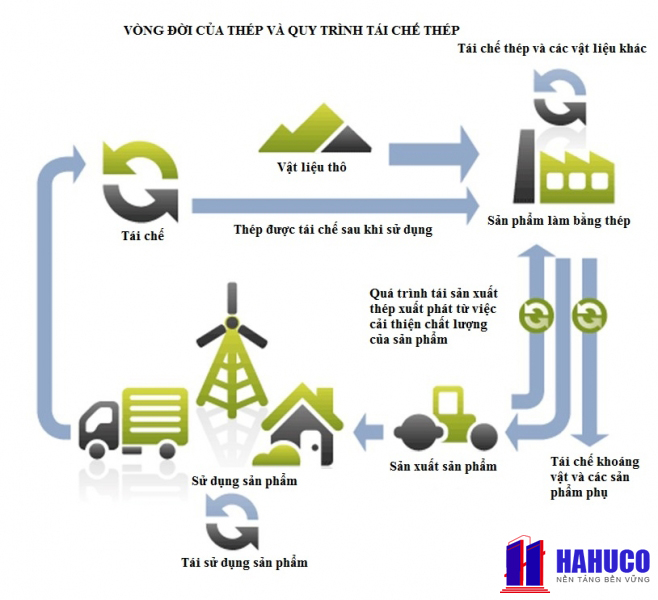

Steel production and recycling

Today, almost all the steel produced by one of two processes worldwide. Basic Oxygen Furnace (BOF) is the main method to convert metallic iron from iron ore into steel making. It needs to use a recycled steel as raw material input and will use 10-25% recycled materials.

This may be indoors or scrap buying scrap originating from the steel items has expired usability. Normally a unit BOF will use all they can scrap and scrap purchased from outside of the missing. Process Electric Arc Furnace second (EAF) can also be converted into steel, but is the main route for steel scrap consumption, and this process requires a minimum of 30% must be at least steel scrap whether to make. EAF operational units from 30 to 100% scrap steel. Some plants use only EAF steel scrap as raw material.

![]() Because steel is a durable material and is used mainly in the relatively stable product (unlike the packing material) and also due to the growing demand, the amount of scrap available (even in proportion very high recycling) are not sufficient to meet demand, so a new steel continues to be produced from iron ore. Many global steel company with production both kiln and can receive and reuse large amounts of steel scrap because scrap steel recycling requires less energy than making new steel.

Because steel is a durable material and is used mainly in the relatively stable product (unlike the packing material) and also due to the growing demand, the amount of scrap available (even in proportion very high recycling) are not sufficient to meet demand, so a new steel continues to be produced from iron ore. Many global steel company with production both kiln and can receive and reuse large amounts of steel scrap because scrap steel recycling requires less energy than making new steel.

Việt Nam

Việt Nam  Tiếng anh

Tiếng anh